With H&C Flex™ flexible duct systems you install confidence. Our products are tested to the highest standards and backed by the best warranty in the industry. Available by the truckload and strategically stocked all over the USA to respond to your needs.

H&C Flex™ offers flexible duct products for both residential and commercial applications that provide the most economical solution to your air-handling needs. H&C Flex™ uses formaldehyde-free, bio-based, environmentally friendly insulation for improved indoor air quality. Available in boxes or bags. Custom lengths available.

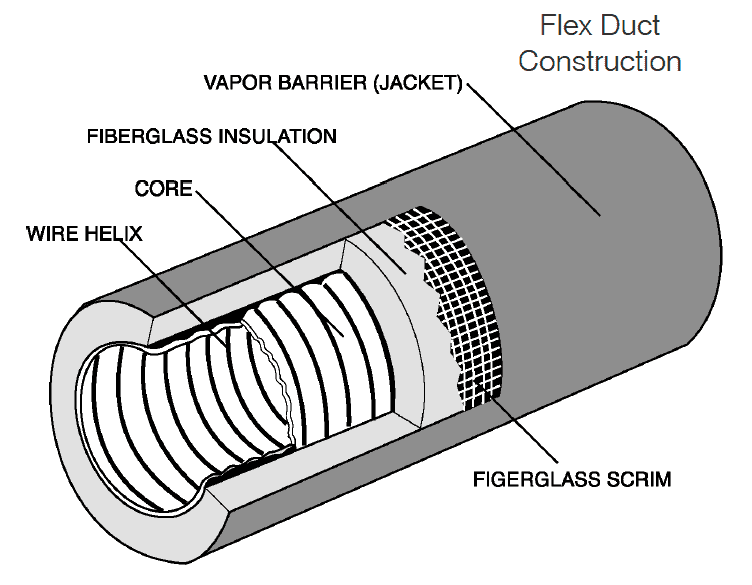

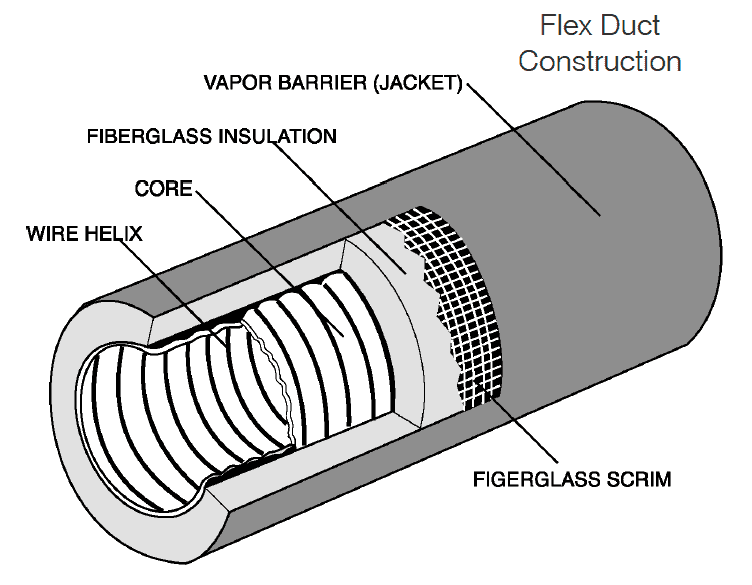

These feature a durable, scuff-resistant black polyethylene vapor barrier that provides improved protection against damaging ultraviolet light. Installation is made easy with the reinforcing fiberglass yarn scrim, which acts as a rip-stop and helps prevent tearing. These air ducts feature an R-value of 4.2, 6.0 or 8.0 to fit any application, and also come in special configurations designed for manufactured homes.

Providing the ultimate in strength and protection, metalized polyester vapor barriers are reinforced with fiberglass scrim to provide high durability and tear resistance. The fiberglass insulation furnishes outstanding thermal protection with R-values of 4.2, 6.0 or 8.0. The metalized jacket air duct and sleeves are available with either a two-ply, black polyester core (Residential Series) or high-pressure, multi-ply, metalized polyester laminate core (Commercial Series) that encapsulate a high carbon steel wire helix.

All H&C Flex™ flexible duct products are protected by the industry's strongest warranty. Our flexible ducts are warranteed to be free of defects in material and workmanship for five (5) years from the date of shipment. (Contact Customer Service for full details.)

All H&C Flex™ flexible duct products are performance-tested in accordance with industry standards to ensure reliability and years of service. Our core is tested (in accordance with ADC FD 72-R1) for actual installation static pressure/ temperature performance and meets the ratings specified in our catalog. Our polyester cores are also tested for microbial resistance by GEI per ASTM D6329-98. The vapor barriers are tested for permeation in accordance with ASTM test methods. Our flex duct systems are performance tested.

All H&C Flex™ flexible duct products meet or exceed the requirements of most federal, state, and local mechanical and energy codes. They comply with the International Mechanical Code (IMC), the Uniform Mechanical Code (UMC), NFPA 90A and 90B, HUD, and the California Bureau of Home Furnishings, just to name a few.

Designed for high pressure applications, air duct connectors utilize either a multi-ply metalized/polyester laminate encapsulating a high carbon steel wire helix or corrugated aluminum for maximum strength and durability.

H&C Flex™ flexible air ducts and air connectors have been rigorously tested by Underwriters Laboratories, Inc. in accordance with UL 181, The Standard for Safety for Factory-Made Air Ducts and Air Connectors. UL is a not-for-profit laboratory with an outstanding reputation for fire safety and performance testing. Our UL listing assures you that our duct cores will not promote the growth of mold.

All H&C Flex™ insulated flexible air ducts have achieved GREENGUARD Gold certification from UL Environment. This certification connects consumers to products certified for low chemical emissions. All H&C Flex™ flexible ducts are listed as Highly Microbial Resistant under the GREENGUARD Gold Microbial Resistance Listing program.

All H&C Flex™ insulated flexible air ducts are certified by the Air Diffusion Council for thermal performance in accordance with the ADC Flexible Duct Performance & Installation Standards (1996). Certified R-values are essential to ensure that the product you buy meets the many regulatory energy codes. Only ADC-certified products will bear this ADC thermal certification marking.